|

|

|

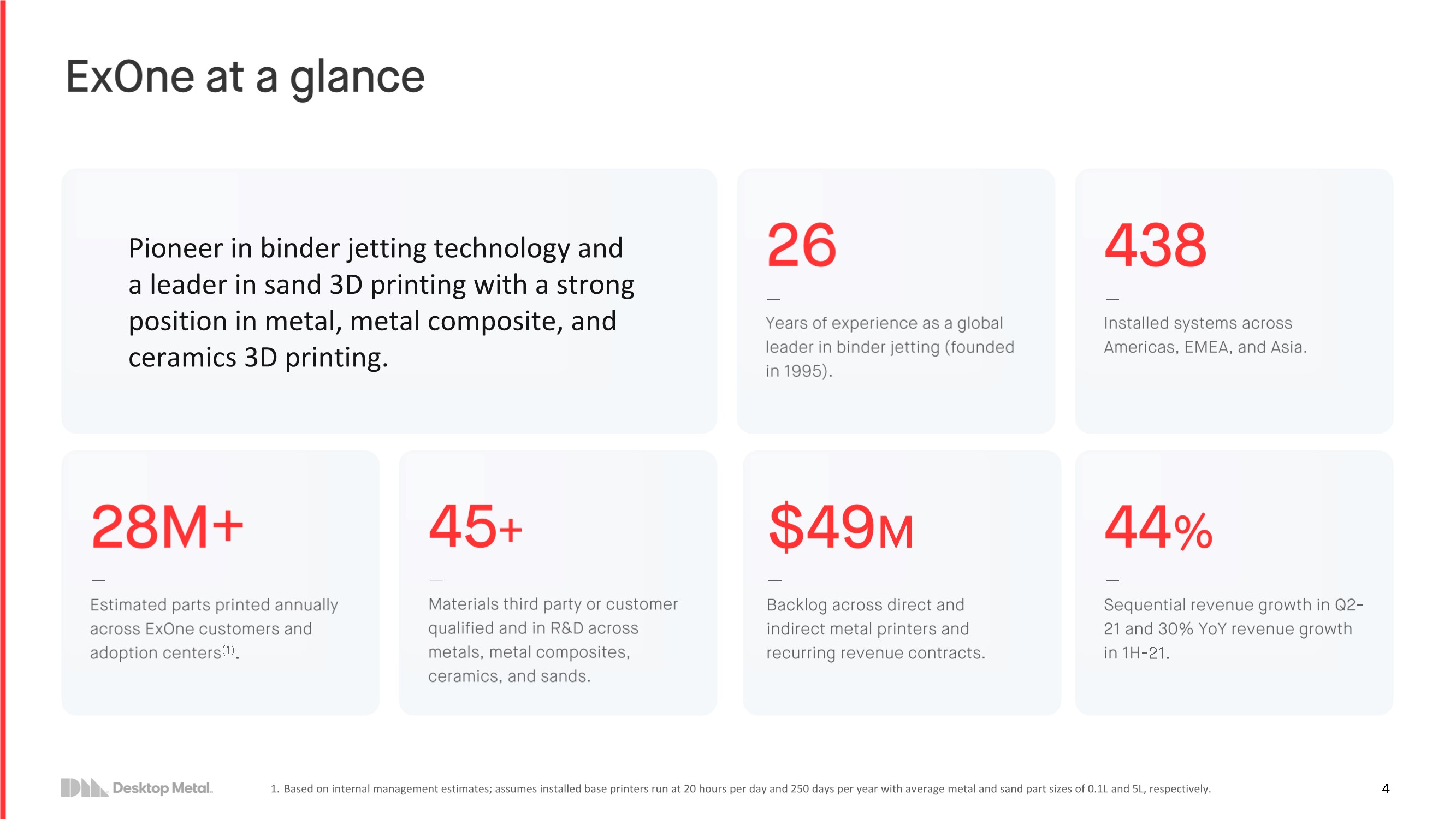

| 1. Based on internal management estimates; assumes installed base printers run at 20 hours per day and 250 days per year with average metal and sand part sizes of 0.1L and 5L, respectively. Pioneer in binder jetting technology and a leader in sand 3D printing with a strong position in metal, metal composite, and ceramics 3D printing. |

|

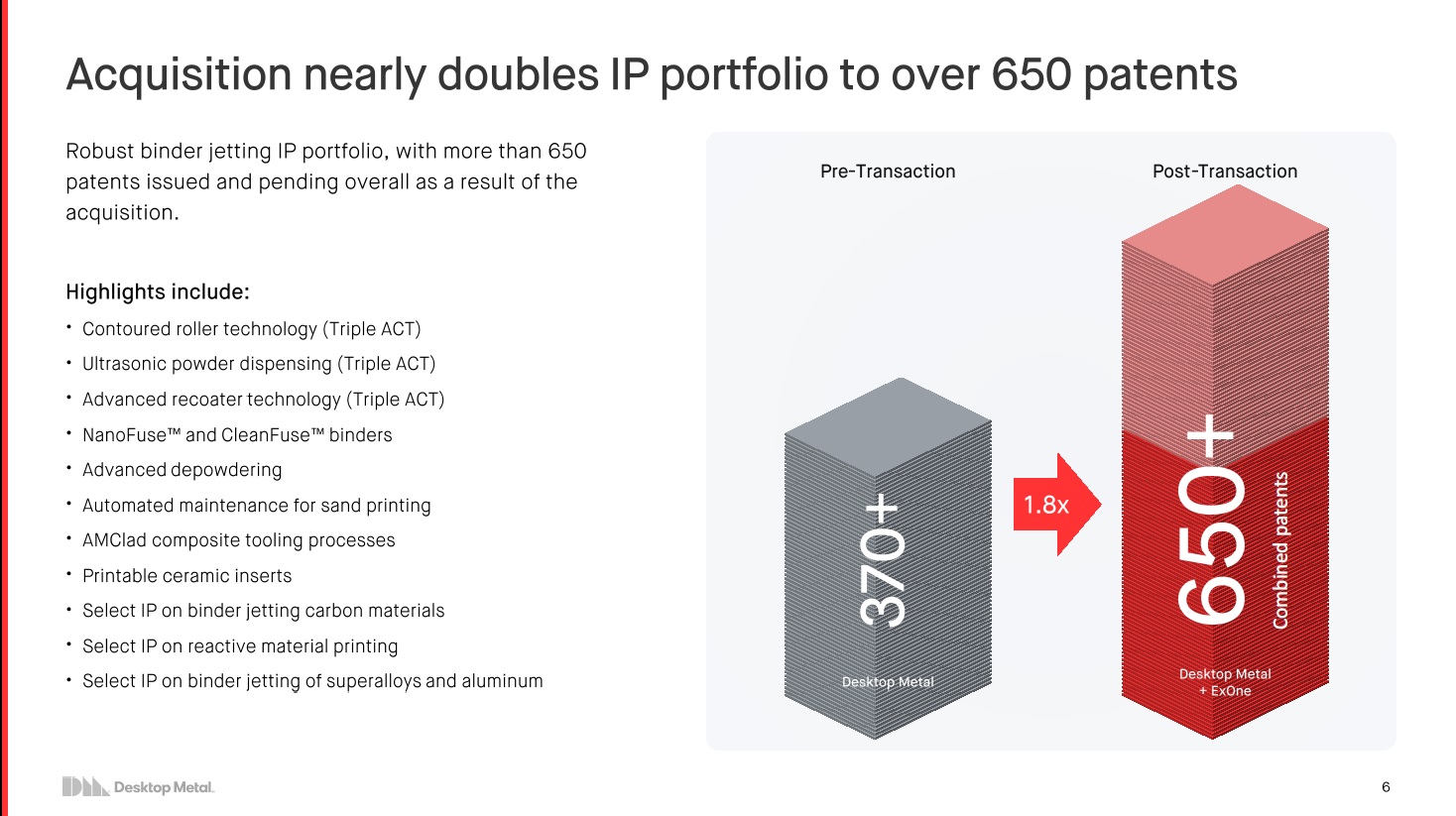

| Combined patents |

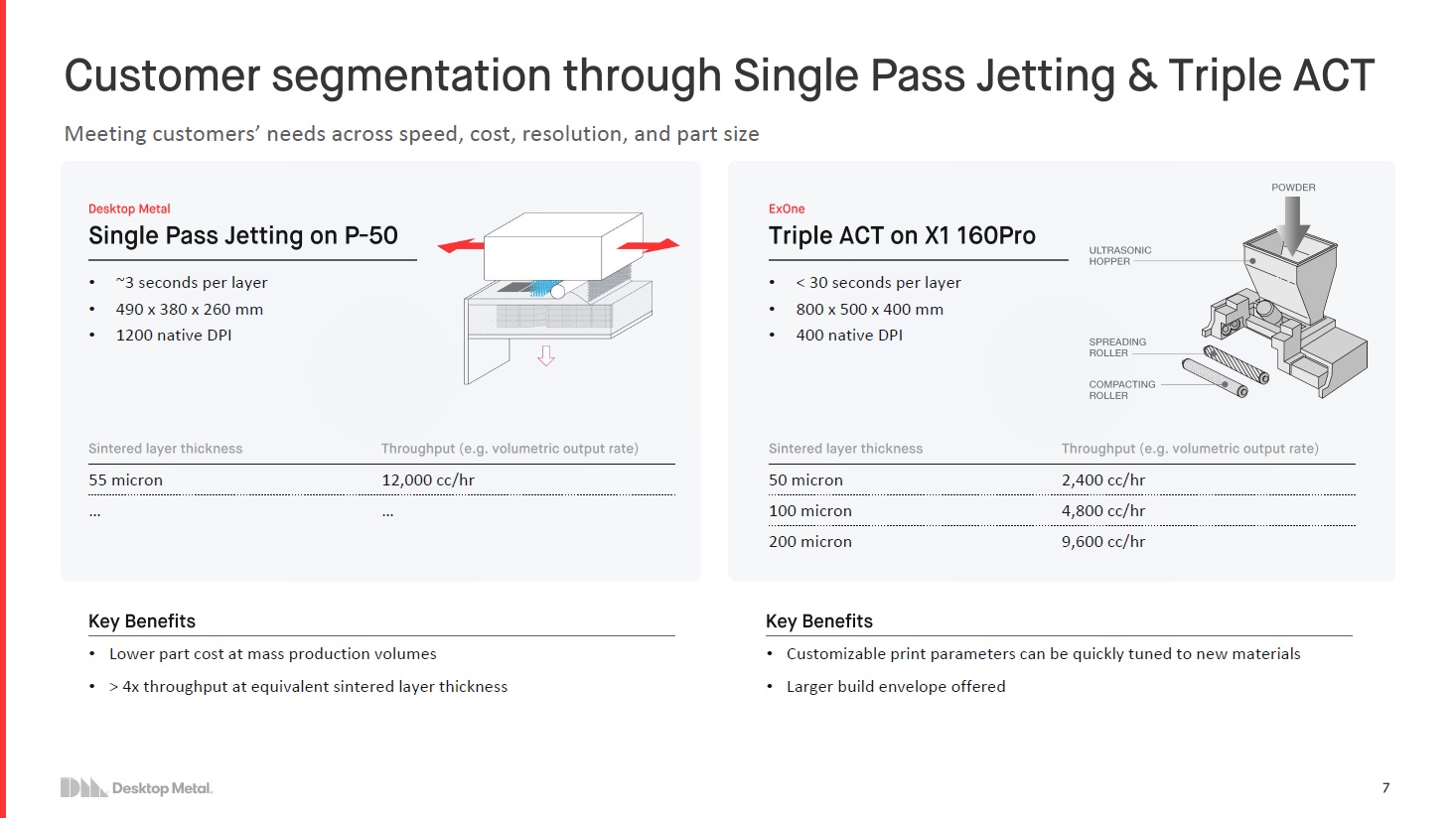

| • ~3 seconds per layer • 490 x 380 x 260 mm • 1200 native DPI • < 30 seconds per layer • 800 x 500 x 400 mm • 400 native DPI Meeting customers’ needs across speed, cost, resolution, and part size 50 micron 2,400 cc/hr 100 micron 4,800 cc/hr 200 micron 9,600 cc/hr 55 micron 12,000 cc/hr …… • Customizable print parameters can be quickly tuned to new materials • Larger build envelope offered • Lower part cost at mass production volumes • > 4x throughput at equivalent sintered layer thickness |

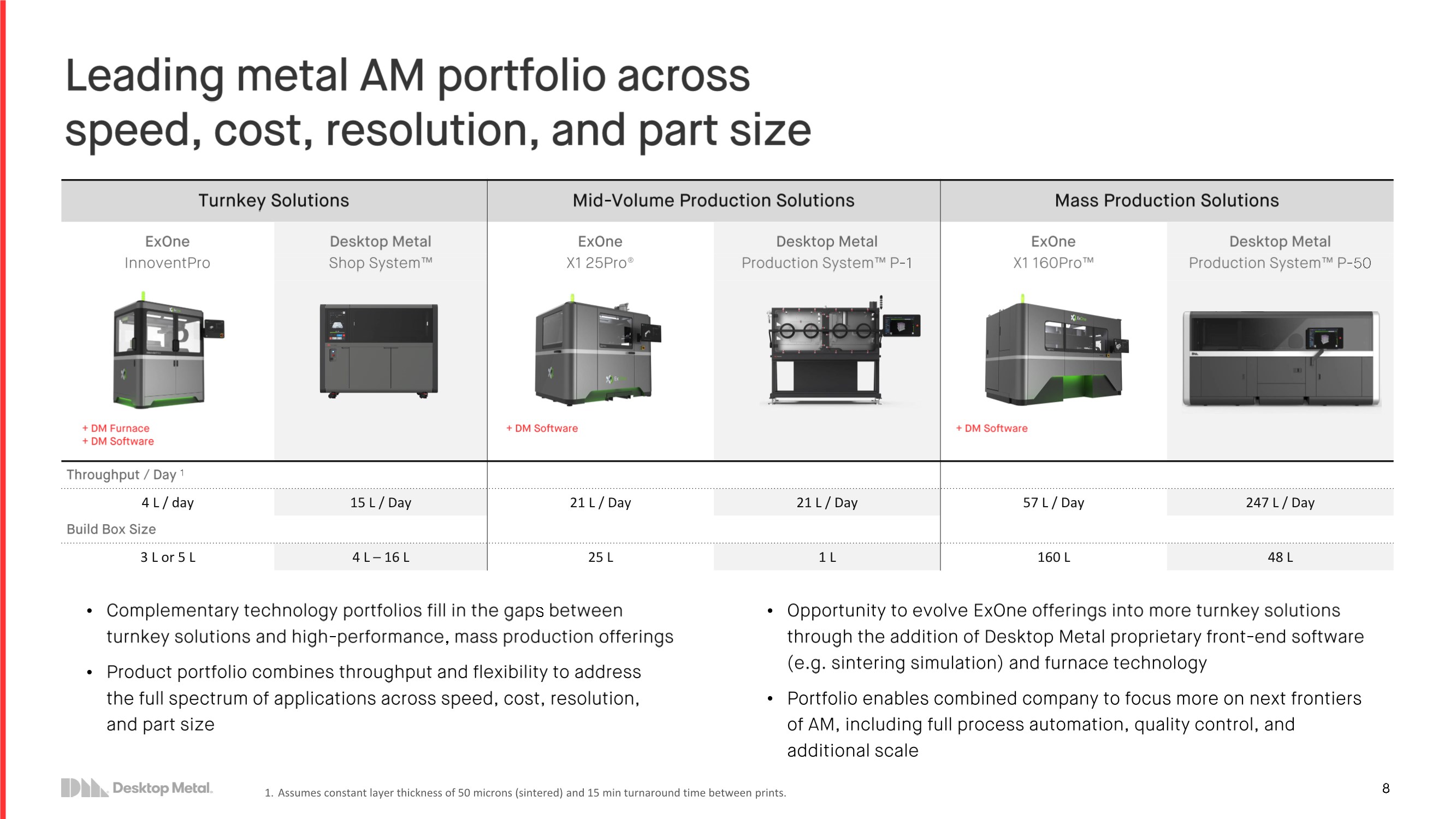

| 1. Assumes constant layer thickness of 50 microns (sintered) and 15 min turnaround time between prints. 4 L / day 15 L / Day 21 L / Day 21 L / Day 57 L / Day 247 L / Day 3 L or 5 L 4 L – 16 L 25 L 1 L 160 L 48 L • • • • |

|

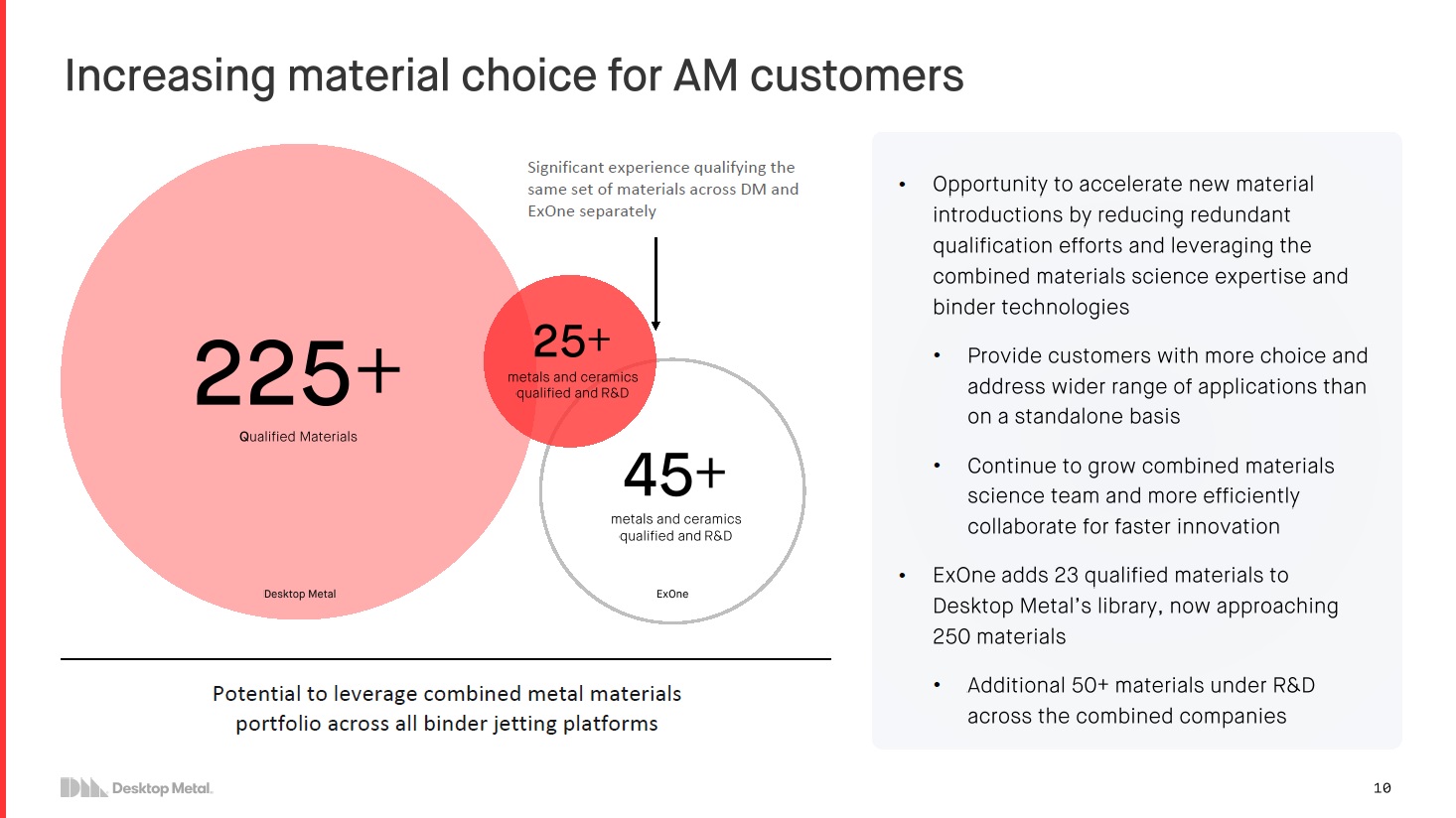

| • • • • • Significant experience qualifying the same set of materials across DM and ExOne separately Potential to leverage combined metal materials portfolio across all binder jetting platforms |

|

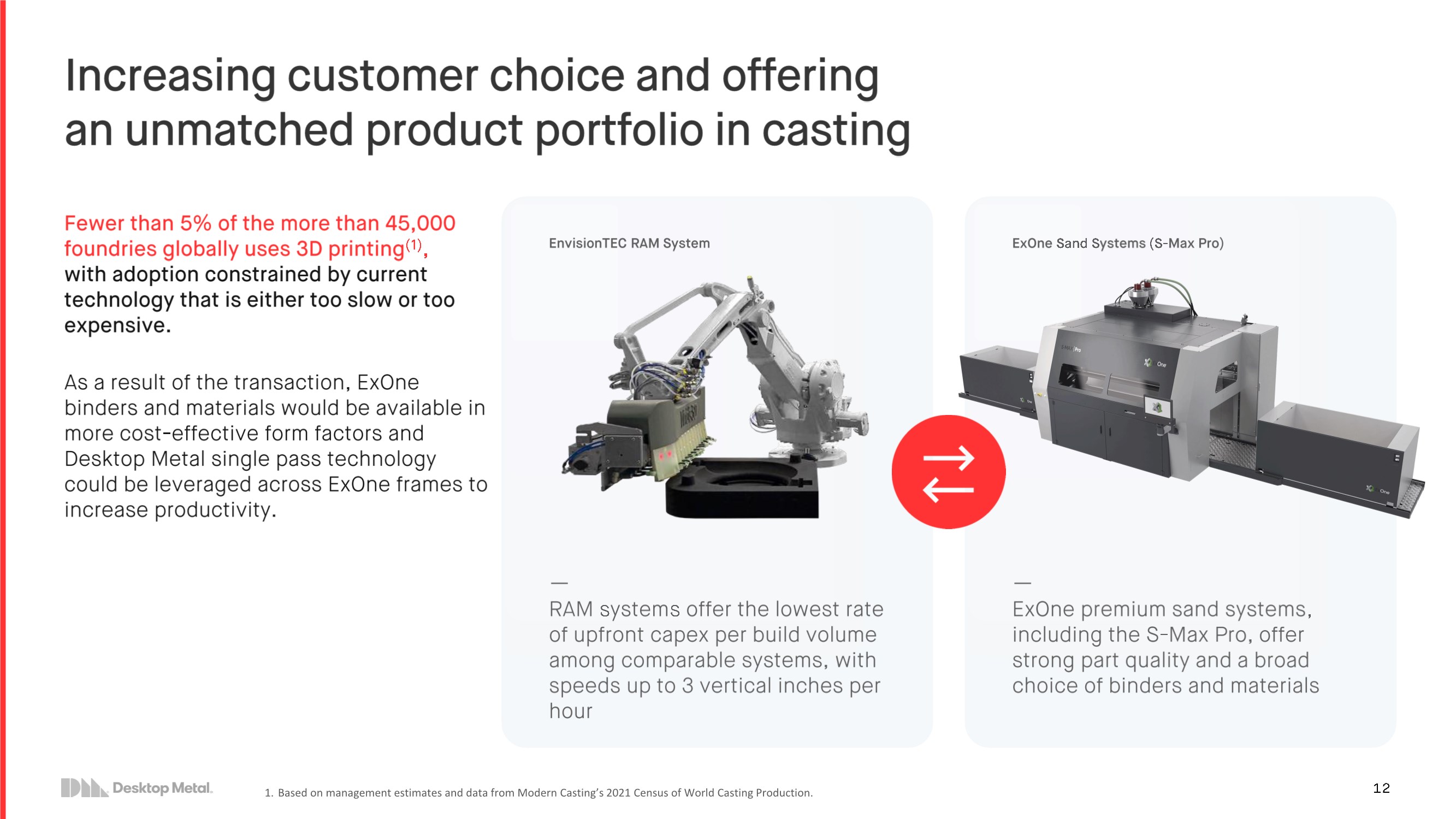

| 1. Based on management estimates and data from Modern Casting’s 2021 Census of World Casting Production. |

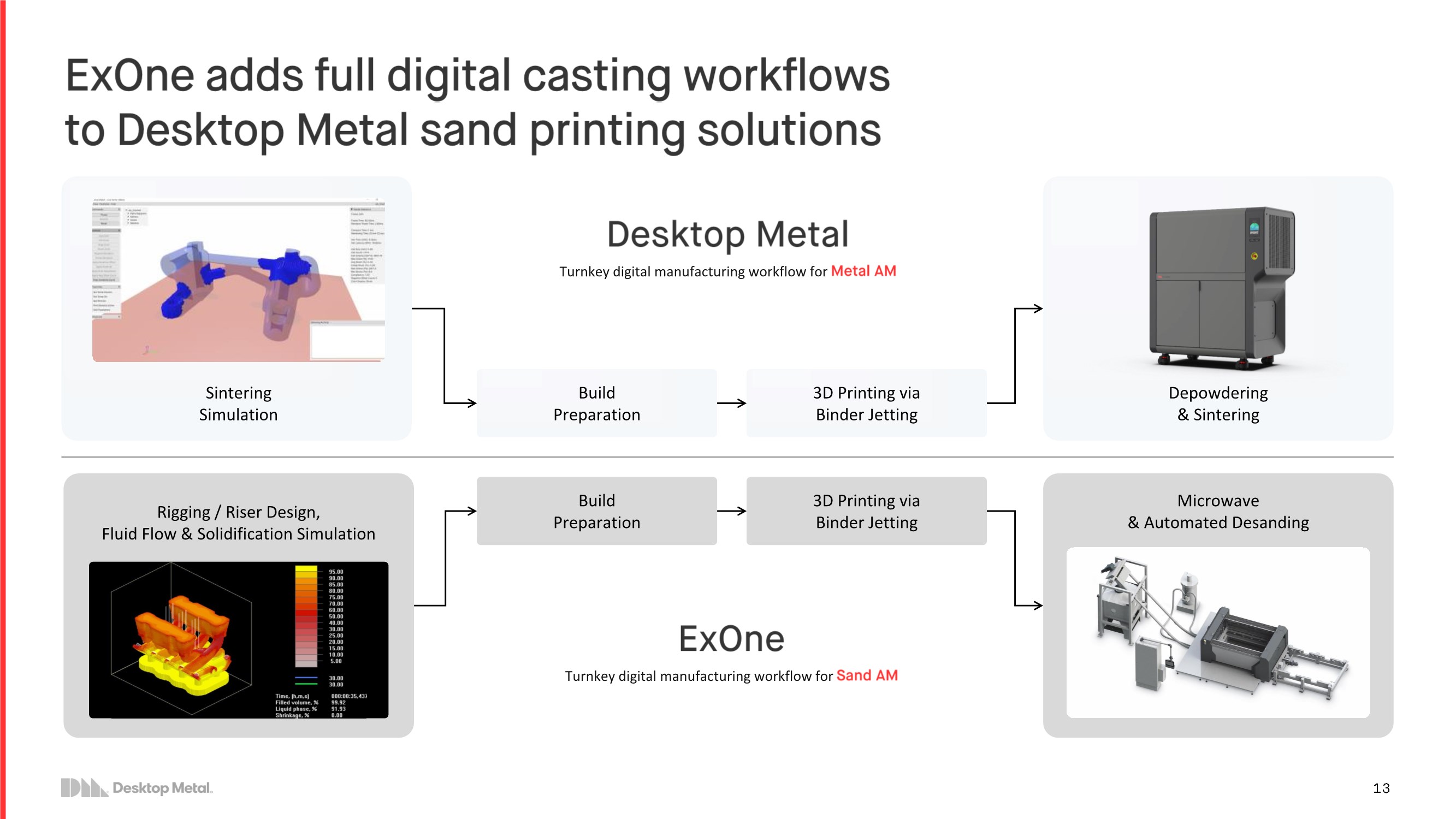

| Build Preparation 3D Printing via Binder Jetting Build Preparation 3D Printing via Binder Jetting Depowdering & Sintering Microwave & Automated Desanding Turnkey digital manufacturing workflow for Turnkey digital manufacturing workflow for Sintering Simulation Rigging / Riser Design, Fluid Flow & Solidification Simulation |

| • • • • • • • • TBU – Images next page |

|

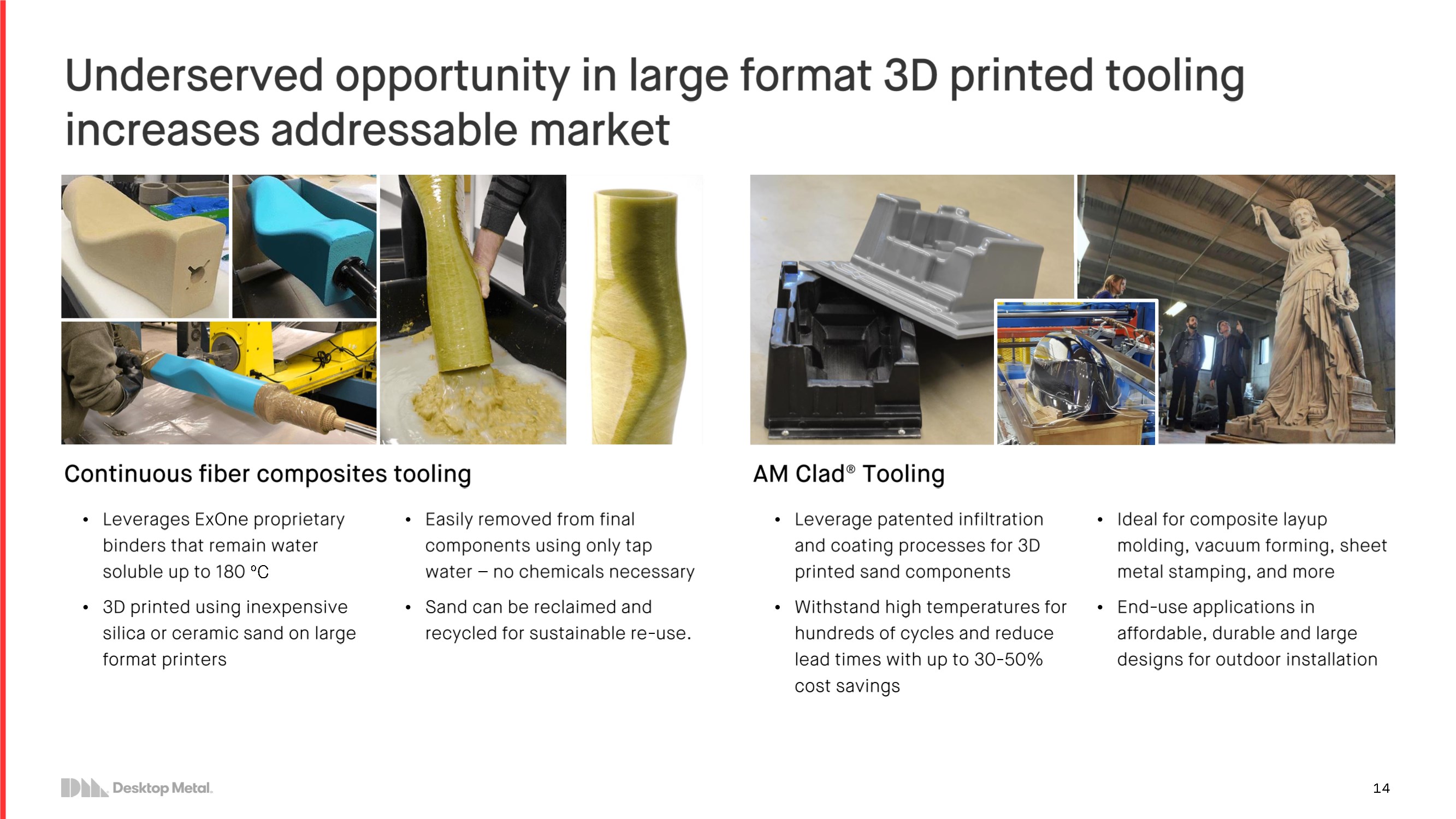

| • • • • • |

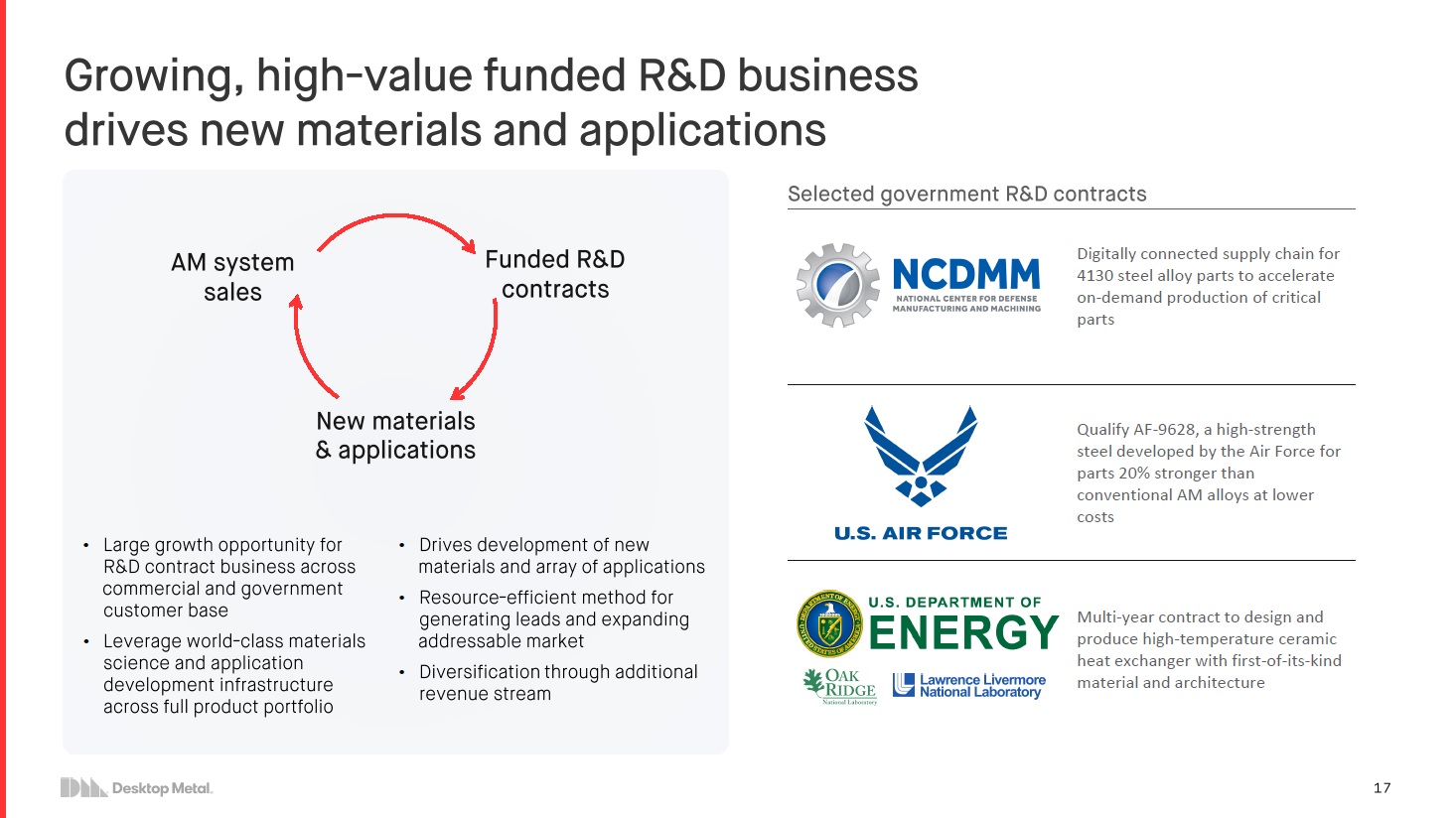

| • • Digitally connected supply chain for 4130 steel alloy parts to accelerate on-demand production of critical parts Qualify AF-9628, a high-strength steel developed by the Air Force for parts 20% stronger than conventional AM alloys at lower costs Multi-year contract to design and produce high-temperature ceramic heat exchanger with first-of-its-kind material and architecture • • • |

|

| In-house manufacturing • World-class facilities in Germany with capacity and expertise to produce large frame systems • Well-suited to more complex and higher BOM cost, multi-component systems Third-party manufacturing • Enables low-cost architectures for turnkey solutions sold through distribution network • Provides inventory for shipping products to customers with low lead-times |

|

|

| DRAFT FOR DISCUSSION PURPOSES ONLY Privileged – Subject to the Review of Counsel |